Packaging

Purpose

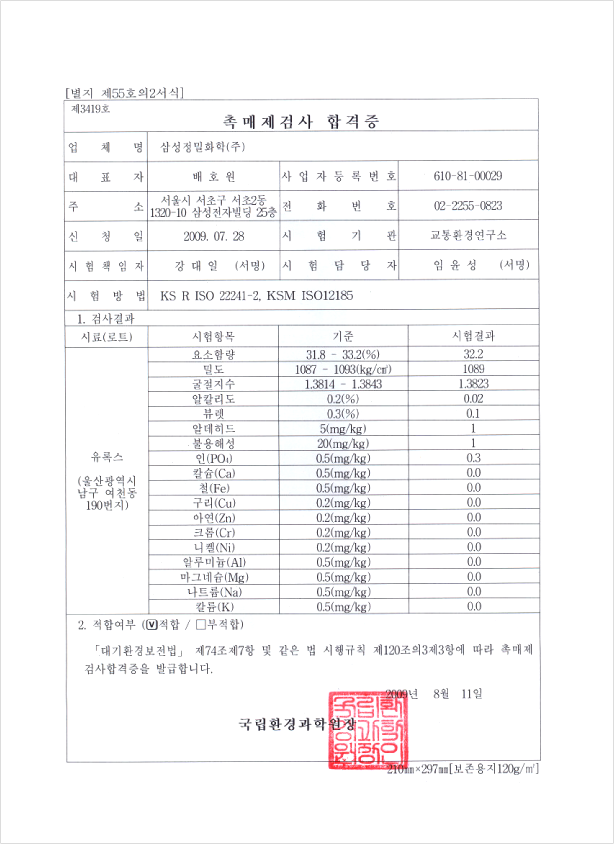

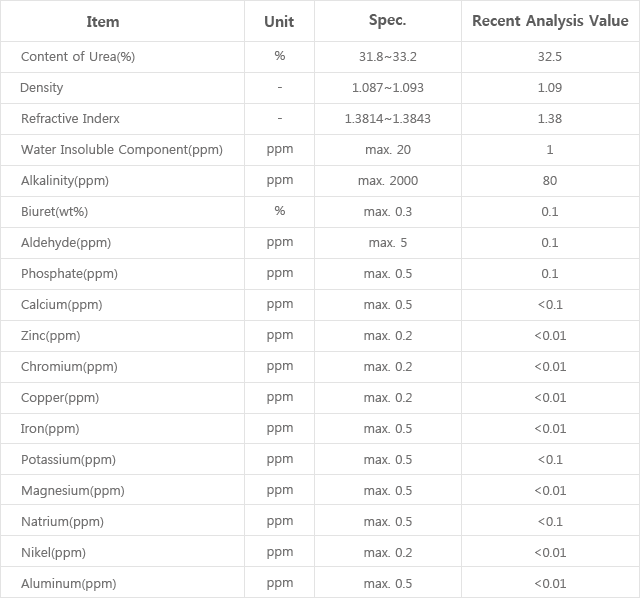

| Item | Unit | Spec. | Typical Value |

|---|---|---|---|

| Content of Urea(%) | % | 31.8~33.2 | 32.5 |

| Density | - | 1.087~1.093 | 1.09 |

| Refractive inderx | - | 1.3814~1.3843 | 1.38 |

| Water Insoluble Component(ppm) | ppm | max. 20 | 1 |

| Alkalinity(ppm) | ppm | max. 2000 | 80 |

| Biuret(wt%) | % | max. 0.3 | 0.1 |

| Aldehyde(ppm) | ppm | max. 5 | 0.1 |

| Phosphate(ppm) | ppm | max. 0.5 | 0.1 |

| Calcium(ppm) | ppm | max. 0.5 | <0.1 |

| Zinc(ppm) | ppm | max. 0.2 | <0.01 |

| Chromium(ppm) | ppm | max. 0.2 | <0.01 |

| Copper(ppm) | ppm | max. 0.2 | <0.01 |

| Iron(ppm) | ppm | max. 0.5 | <0.01 |

| Potassium(ppm) | ppm | max. 0.5 | <0.1 |

| Magnesium(ppm) | ppm | max. 0.5 | <0.01 |

| Natrium(ppm) | ppm | max. 0.5 | <0.1 |

| Nikel(ppm) | ppm | max. 0.2 | <0.01 |

| Aluminum(ppm) | ppm | max. 0.5 | <0.01 |

| Item | Unit | Spec. | Typical Value |

|---|---|---|---|

| Content of Urea(%) | % | 31.8~33.2 | 32.5 |

| Density | - | 1.087~1.093 | 1.09 |

| Refractive inderx | - | 1.3814~1.3843 | 1.38 |

| Water Insoluble Component(ppm) | ppm | max. 20 | 1 |

| Alkalinity(ppm) | ppm | max. 2000 | 80 |

| Biuret(wt%) | % | max. 0.3 | 0.1 |

| Aldehyde(ppm) | ppm | max. 5 | 0.1 |

| Phosphate(ppm) | ppm | max. 0.5 | 0.1 |

| Calcium(ppm) | ppm | max. 0.5 | <0.1 |

| Zinc(ppm) | ppm | max. 0.2 | <0.01 |

| Chromium(ppm) | ppm | max. 0.2 | <0.01 |

| Copper(ppm) | ppm | max. 0.2 | <0.01 |

| Iron(ppm) | ppm | max. 0.5 | <0.01 |

| Potassium(ppm) | ppm | max. 0.5 | <0.1 |

| Magnesium(ppm) | ppm | max. 0.5 | <0.01 |

| Natrium(ppm) | ppm | max. 0.5 | <0.1 |

| Nikel(ppm) | ppm | max. 0.2 | <0.01 |

| Aluminum(ppm) | ppm | max. 0.5 | <0.01 |

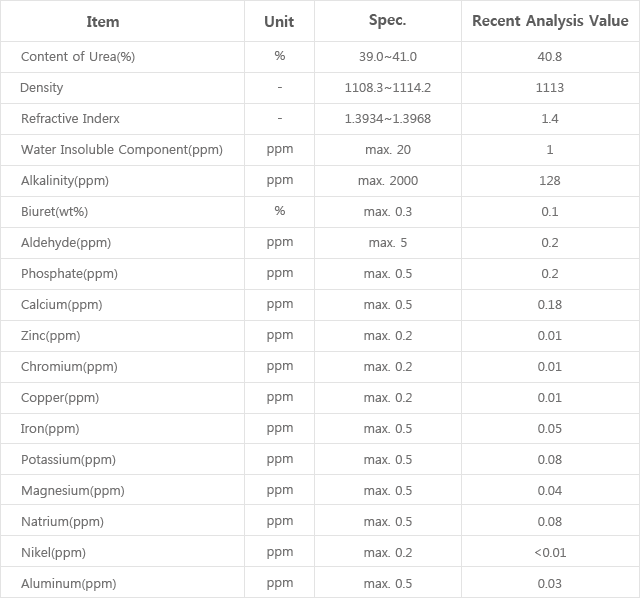

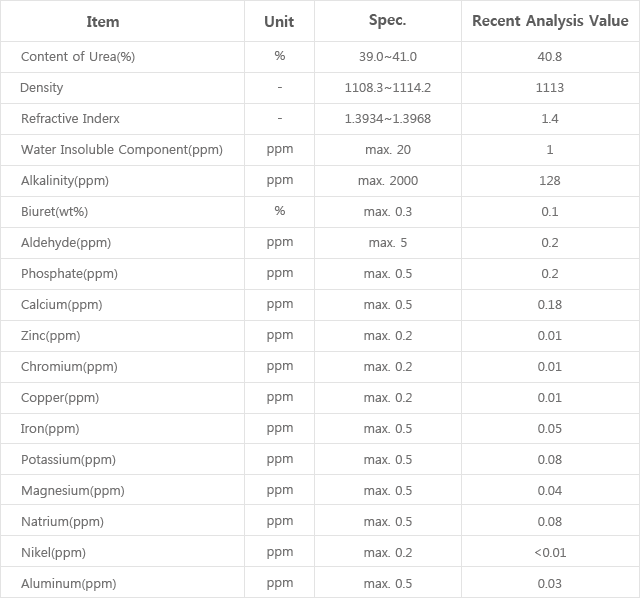

| Item | Unit | Spec. | Typical Value |

|---|---|---|---|

| Content of Urea(%) | % | 39.0~41.0 | 40.8 |

| Density | - | 1108.3~1114.2 | 1113 |

| Refractive inderx | - | 1.3934~1.3968 | 1.4 |

| Water Insoluble Component(ppm) | ppm | max. 50 | 1 |

| Alkalinity(ppm) | ppm | max. 0.5 | 128 |

| Biuret(wt%) | % | max. 0.8 | 0.1 |

| Aldehyde(ppm) | ppm | max. 100 | 0.2 |

| Phosphate(ppm) | ppm | max. 1 | 0.2 |

| Calcium(ppm) | ppm | max. 1 | 0.18 |

| Zinc(ppm) | ppm | max. 0.2 | 0.01 |

| Chromium(ppm) | ppm | max. 0.2 | 0.01 |

| Copper(ppm) | ppm | max. 0.2 | 0.01 |

| Iron(ppm) | ppm | max. 1 | 0.05 |

| Potassium(ppm) | ppm | max. 1 | 0.08 |

| Magnesium(ppm) | ppm | max. 1 | 0.04 |

| Natrium(ppm) | ppm | max. 1 | 0.08 |

| Nikel(ppm) | ppm | max. 0.2 | <0.01 |

| Aluminum(ppm) | ppm | max. 0.5 | 0.03 |

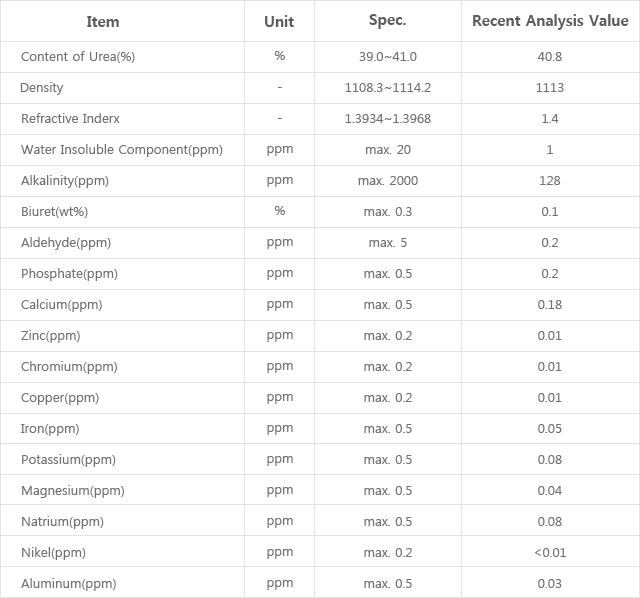

| Item | Unit | Spec. | Typical Value |

|---|---|---|---|

| Content of Urea(%) | % | 39.0~41.0 | 40.8 |

| Density | - | 1108.3~1114.2 | 1113 |

| Refractive inderx | - | 1.3934~1.3968 | 1.4 |

| Water Insoluble Component(ppm) | ppm | max. 50 | 1 |

| Alkalinity(ppm) | ppm | max. 0.5 | 128 |

| Biuret(wt%) | % | max. 0.8 | 0.1 |

| Aldehyde(ppm) | ppm | max. 100 | 0.2 |

| Phosphate(ppm) | ppm | max. 1 | 0.2 |

| Calcium(ppm) | ppm | max. 1 | 0.18 |

| Zinc(ppm) | ppm | max. 0.2 | 0.01 |

| Chromium(ppm) | ppm | max. 0.2 | 0.01 |

| Copper(ppm) | ppm | max. 0.2 | 0.01 |

| Iron(ppm) | ppm | max. 1 | 0.05 |

| Potassium(ppm) | ppm | max. 1 | 0.08 |

| Magnesium(ppm) | ppm | max. 1 | 0.04 |

| Natrium(ppm) | ppm | max. 1 | 0.08 |

| Nikel(ppm) | ppm | max. 0.2 | <0.01 |

| Aluminum(ppm) | ppm | max. 0.5 | 0.03 |

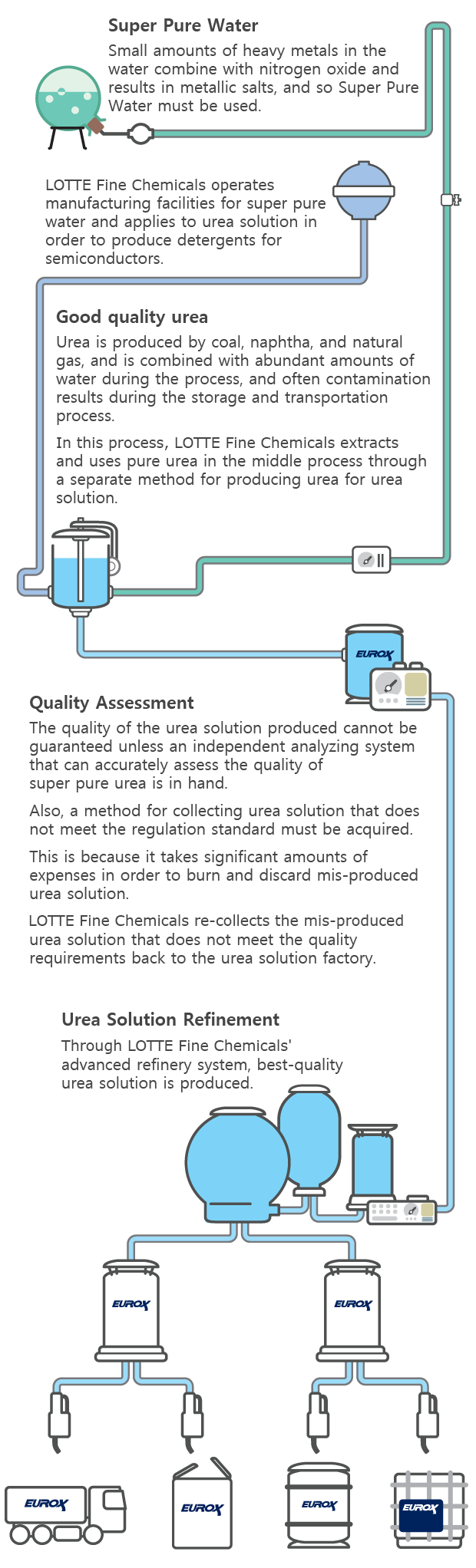

Manufacturing Process

Small amounts of heavy metals in the water combine with nitrogen oxide and results in metallic salts, and so Super Pure Water must be used.

LOTTE Fine Chemical operates manufacturing facilities for super pure water and applies to urea solution in order to produce detergents for semiconductors.

Urea is produced by coal, naphtha, and natural gas, and is combined with abundant amounts of water during the process, and often contamination results during the storage and transportation process.

In this process, LOTTE Fine Chemical extracts and uses pure urea in the middle process through a separate method for producing urea for urea solution.

The quality of the urea solution produced cannot be guaranteed unless an independent analyzing system that can accurately assess the quality of super pure urea is in hand.

Also, a method for collecting urea solution that does not meet the regulation standard must be acquired.

This is because it takes significant amounts of expenses in order to burn and discard mis-produced urea solution.

LOTTE Fine Chemical re-collects the mis-produced urea solution that does not meet the quality requirements back to the urea solution factory.

Through LOTTE Fine Chemical’ advanced refinery system, best-quality urea solution is produced.

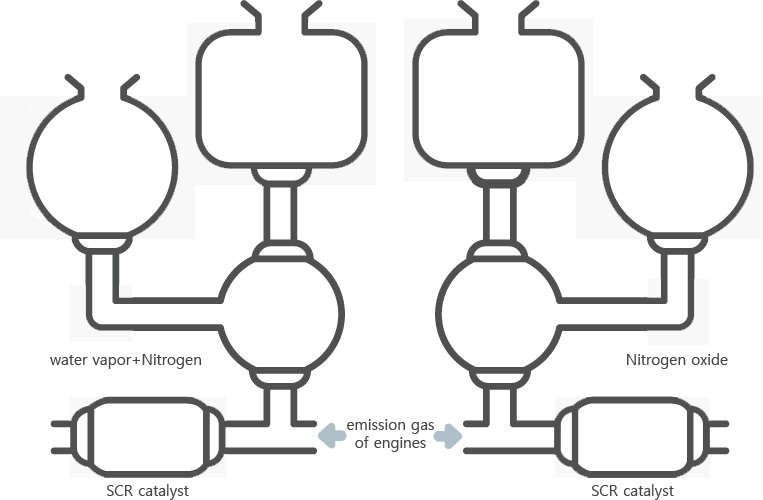

Quality Importance

Reason for selecting good quality urea solution

Compressed Air

O2N2

Compressed Air

O2N2

To conclude, a good quality urea solution is an urea solution that has the lowest amount of heavy metal components.

The lowest amount it has, the longer it can be used and vehicles and the environment will be protected.